PRODUCT OFFERING FOR ONE-COMPONENT EPOXY COMPOSITES

Cardolite offers CNSL-based novolac resins that can be used as cross linkers for one-component epoxy resins used in prepregs and pultrusion processes. Formulators looking for high bio-content, application-friendly, and high performance solutions can benefit from our offering.

LONG POT LIFE

CNSL-based novolac resins (NX-4000 Series) are a new family of high bio-content phenolic resins that can be formulated as epoxy crosslinkers in long pot life, heat-cured systems. This class of low and high viscosity novolacs is high in functionality and equivalent weight. These products give excellent moisture and chemical resistance, and improved wetting properties and interlaminar shear strength and adhesion to composite parts.

CNSL novolacs have very good miscibility with epoxy resins and could be alternatives to or used in combination with petroleum based phenolic resins depending on the system. They are suitable as high biocontent, increased flexibility replacements of latent amines and anhydride curing agents in long pot life and latent systems. CNSL novolacs do not react with epoxy at room temperature, but react at moderate temperatures (80-120°C) in the presence of a catalyst such as imidazole, urone, or Lewis acids. Among the suggested accelerators are 2-ethyl,4-methylimidazole, 2-methylimidazole, blocked imidazole and boron trifluoride complex. The choice of the catalyst determines the pot life of the formulation and the cure time at different temperatures.

These novolacs can be used in one or two component epoxy formulations.

EXCELLENT WATER AND CHEMICAL RESISTANCE WITH GOOD MECHANICAL PROPERTIES

CNSL-based novolacs are very hydrophobic due to the long aliphatic side chain and aromatic ring of cardanol, which provides excellent water and chemical resistance, coupled with high bio-based content and a wide formulation latitude.

A wide range of mechanical properties can be achieved by varying the catalyst and use levels of epoxy systems in combination with CNSL Novolacs. High Tg can be obtained by using 2phr blocked imidazole and 5phr of NX-4001 with solid/liquid epoxy blend. High Tg and low onset temperature can be achieved using imidazole and reduced use levels of NX-4004 and NX-4005.

IMPROVED INTERLAMINAR ADHESION AND VIBRATION DAMPING

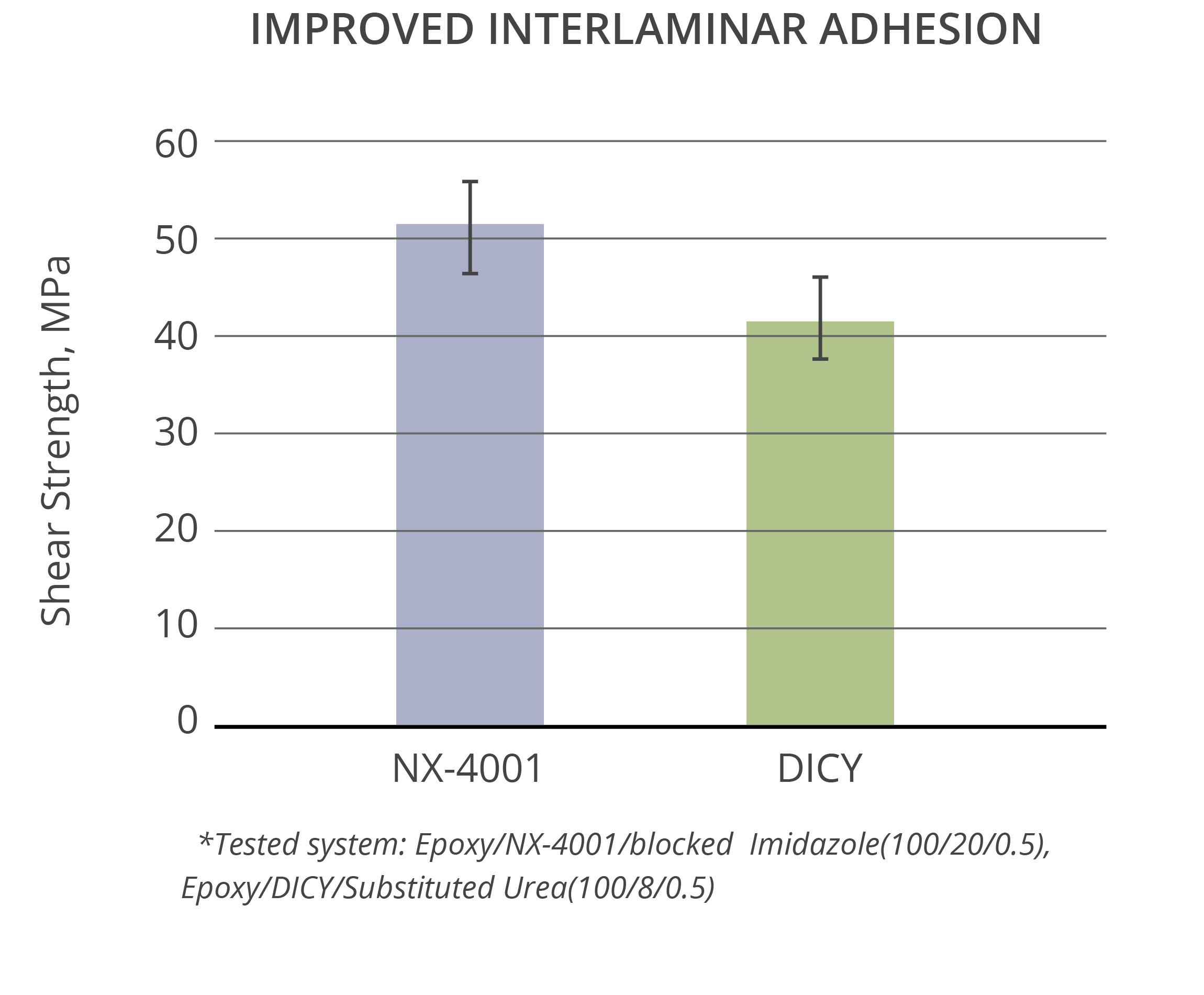

The unique chemical structure of CNSL-based novolacs improves fiber wetting and adhesion, resulting in a significant increase in interlaminar adhesion.

Apparent interlaminar shear strength was determined on cured prepreg samples using ASTM 2344M-00 short beam flexural test. The test shows that CNSL-based novolac, used at 20 phr in an epoxy system, improves interlaminar shear strength by 22% compared with a dicyandiamide cured system.

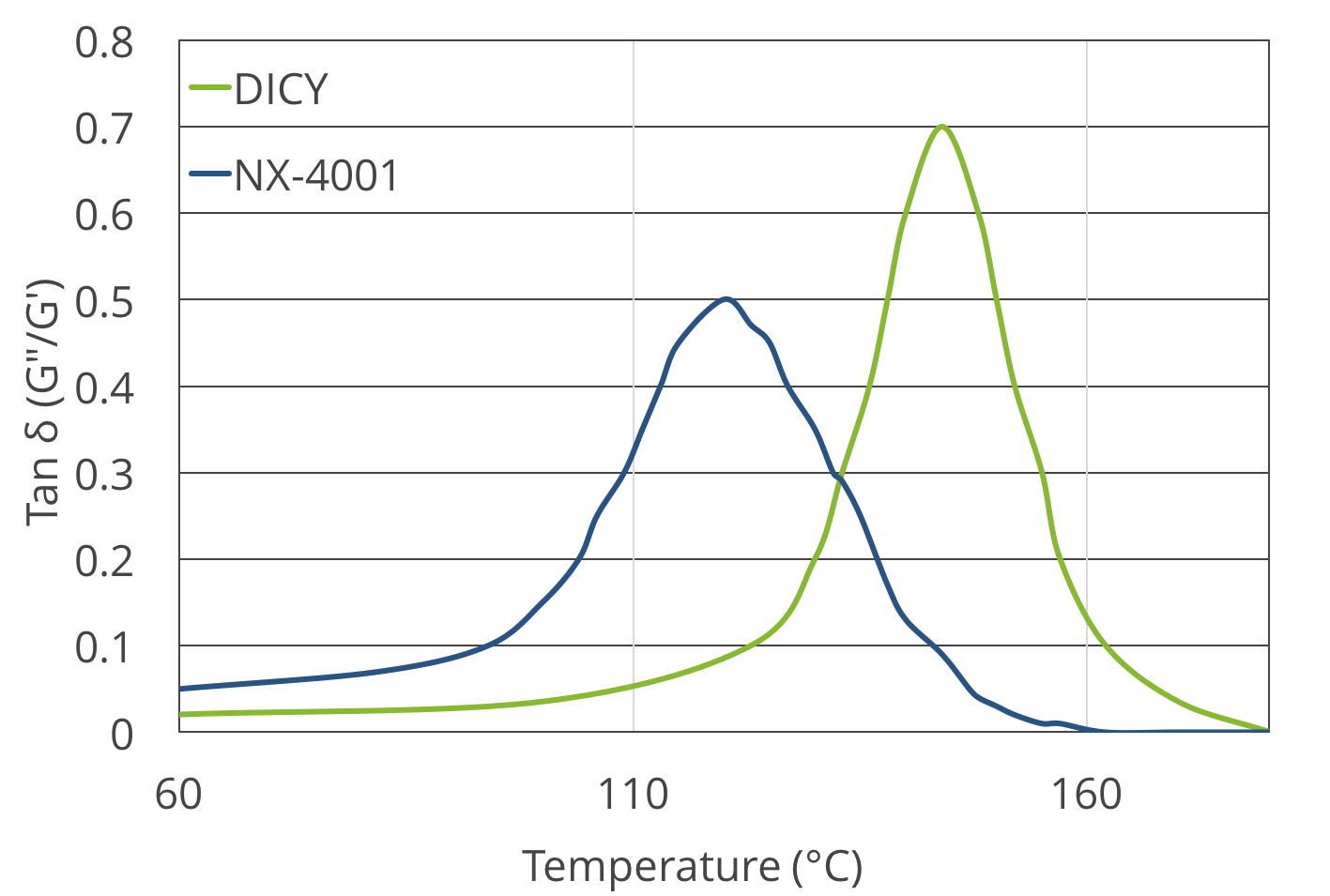

DMA analysis performed on comparative prepregs with dicyandiamide or NX-4001 (20% by weight) as epoxy crosslinker shows that the initial energy dissipation, tan δ, of the material is higher for the NX-4001 based prepreg, therefore indicating a higher dampening capacity. This is confirmed by additional resonance tests that show 37% improvement in vibration dampening at various frequencies (Data courtesy of SHD Composite Materials Ltd.).