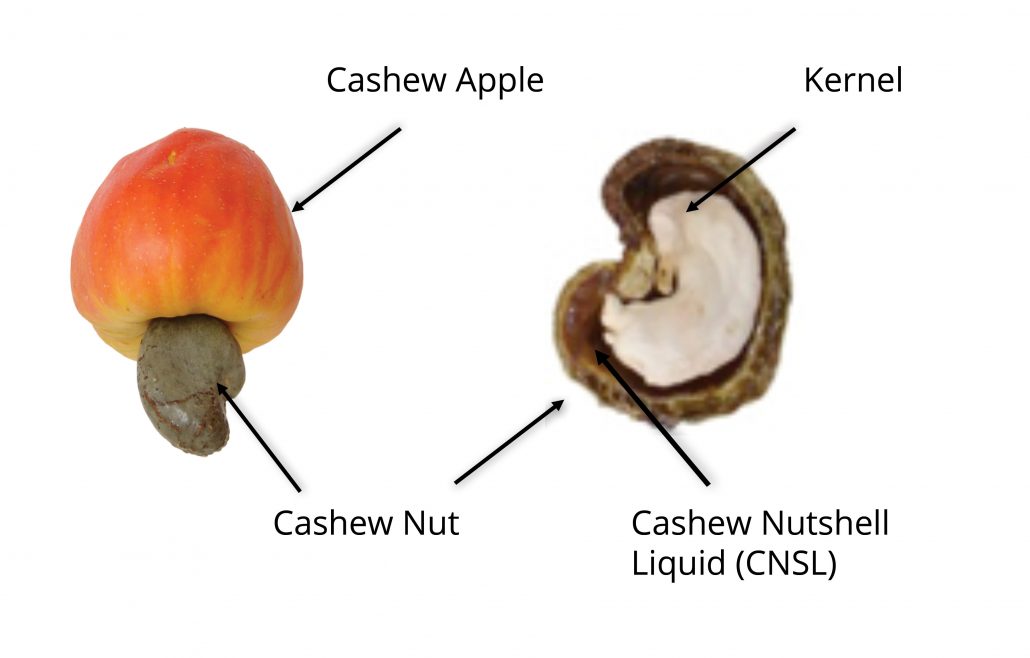

Cardolite products are based on cashew nutshell liquid (CNSL), a natural, non-food chain, and annually renewable biomaterial. CNSL is a reddish brown viscous liquid extracted from a soft honeycomb structure inside the cashew nutshell.

This nutshell liquid contains mainly anacardic acid and a smaller amount of cardol and its methyl derivatives. CNSL can be decarboxylated and distilled to yield high purity cardanol, a highly desirable alkylphenolic compound in the chemical industry. The distillation residue can be used to produce resilient friction particles and binders for the automotive brake lining industry.

Cardolite’s proprietary technology allows for the production of a wide range of cardanol grades with different purities and colors. Recently developed Ultra LITE technology allows for color Gardner 1 cardanols with good stability over time.

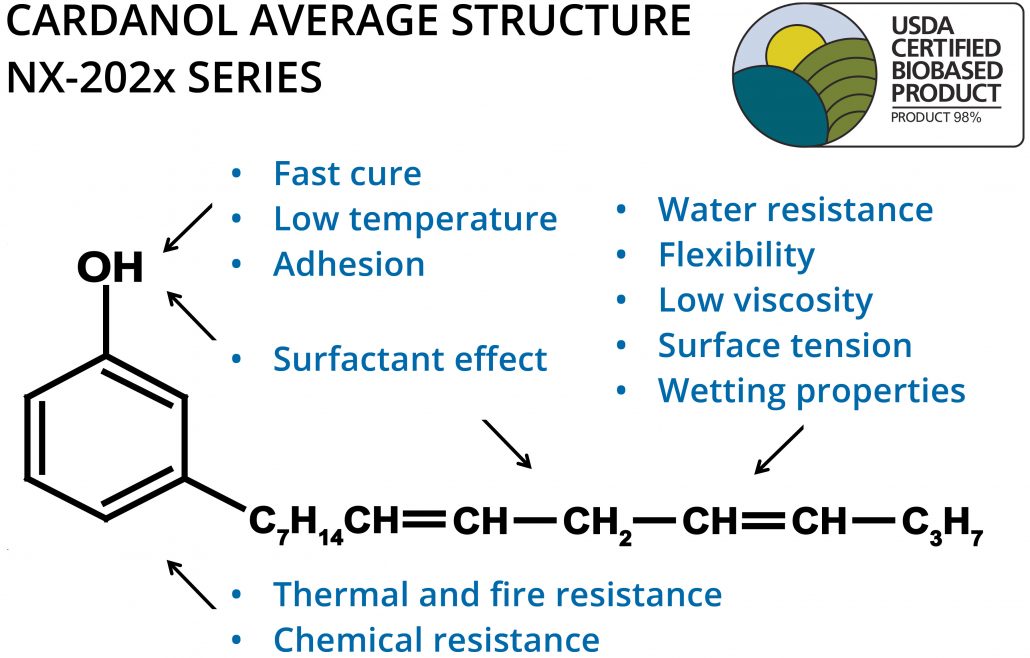

Cardanol is used as a primary building block for Cardolite’s epoxy curing agents, diluents and modifiers, and polyol and diol resins. This natural alkylphenolic material has an aromatic ring that provides a strong chemical and thermal resistant backbone while the hydroxyl group gives strong adhesion and good reactivity for fast and low temperature cure. A long aliphatic side chain provides excellent water and moisture resistance, good flexibility, low viscosity, extended pot life, and excellent corrosion protection. Our cardanol product line, the NX-202x Series, has earned the USDA Certified Bio-based Product label.

With the increased desire in the chemical industry to replace petroleum-based materials and move away from toxic substances, cardanol end-uses continue to expand as a diluent and intermediate for various derivatives and applications

Specialty cardanol grade, NX-2026, showed favorable results compared to petro-based counterpart in a recent life cycle analysis (LCA) conducted by the nova-Institut in Germany. LCA is a process to evaluate and quantify the environmental burdens associated with a product, process, or activity by identifying and quantifying energy and materials used and wastes released to the environment during their life cycle.

A cradle-to-gate scenario (cultivation of cashew trees to the factory gate) showed that the use of NX-2026 instead of nonyl phenol significantly reduces Global Warming Potential due to CO2 uptake by cashew trees. NX-2026 also showed lower abiotic depletion potential of fossil fuels than nonyl phenol.

Please watch this quick video for more details on this assessment.

NX-2026 LIFE CYCLE ANALYSIS RESULTS

SUSTAINABLE INNOVATION

Cardolite continues to invest heavily on innovation that leverages the unique properties of CNSL technology. Our advanced research and technical service laboratories use CNSL as a primary building block to develop and evaluate performance of specialty materials with demonstrated advantages over traditional chemistries.

PHENALKAMINES

Phenalkamines share some similar advantages to other Mannich base curing agents, such as: extremely fast cure, low temperature cure (even below 0°C), good chemical resistance, good surface appearance, good moisture tolerance, and non-blushing properties. However, due to the long aliphatic side chain of cardanol, phenalkamines also have very good pot life, good flexibility, surface tolerance, and excellent water and salt water resistance.

PHENALKAMIDES

Cardolite phenalkamide technology is a new category of epoxy curing agent that fills a gap between polyamide and phenalkamine technologies. By chemically combining the two technologies, phenalkamide curing agents offer the benefits of both while mitigating their limitations.

WATERBORNE CURING AGENTS

Cardolite offers a wide range of curing agents designed for waterborne epoxy coatings. Our portfolio includes solution-type and emulsion-type chemistries with excellent compatibility with most epoxy dispersions. Grades supplied in water do not contain any solvents. Our curing agents are great options for anticorrosion primers, self-levelers, and midcoats. Some grades are specially formulated for concrete floors and top coats.

CNSL POLYOLS AND DIOLS

Cardolite offers a line of renewable, cashew nutshell liquid (CNSL) based polyols and diols that have unique qualities compared to widely known polyester and polyether polyols, and other natural oil based polyols. These materials are very hydrophobic providing less moisture sensitivity during cure with isocyanate and they deliver excellent hydrolytic stability and mechanical strength to polyurethanes.

POLYURETHANE CENTER

Cardolite offers innovative, renewable products for polyurethane applications that include novel polyols and diols, NCO blocking agents, reactive and non-reactive diluents, and ethoxylated surfactants. These are generally high bio content products that can enhance the performance of polyurethane coatings, adhesives, elastomers, and foams.