Diluents & Modifiers Portfolio

Reactive Diluents

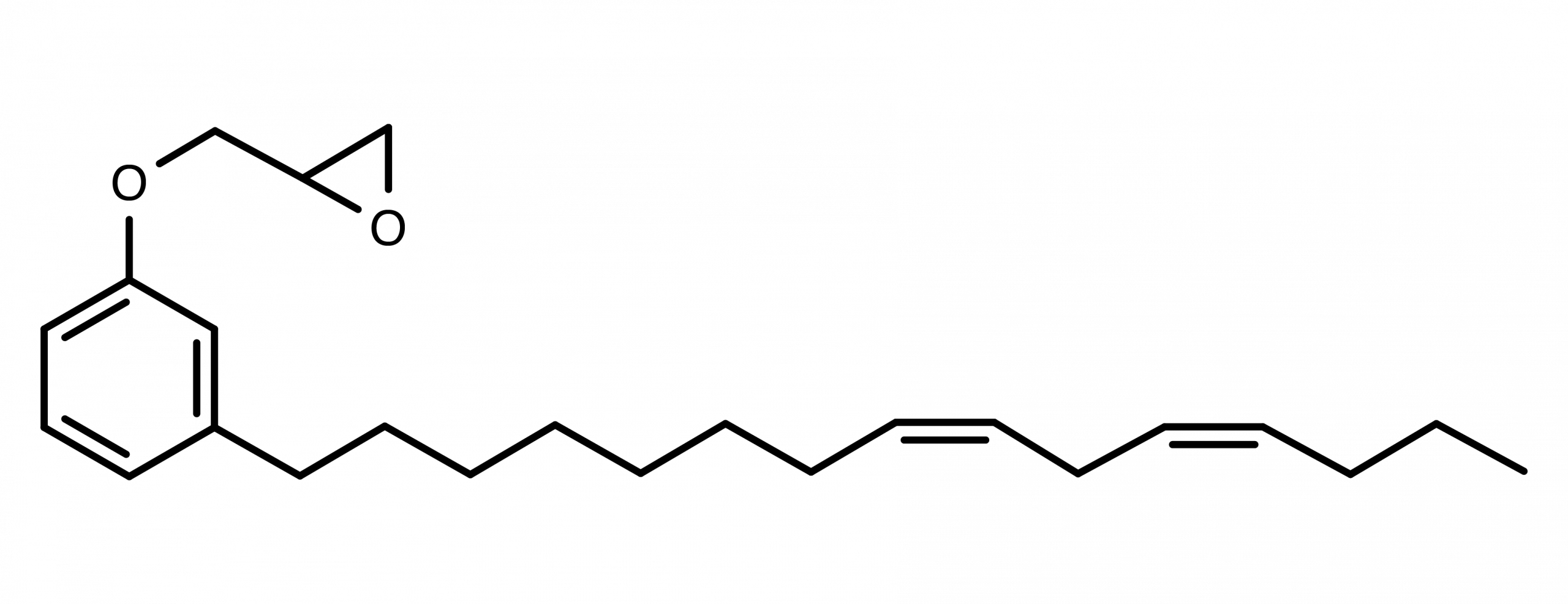

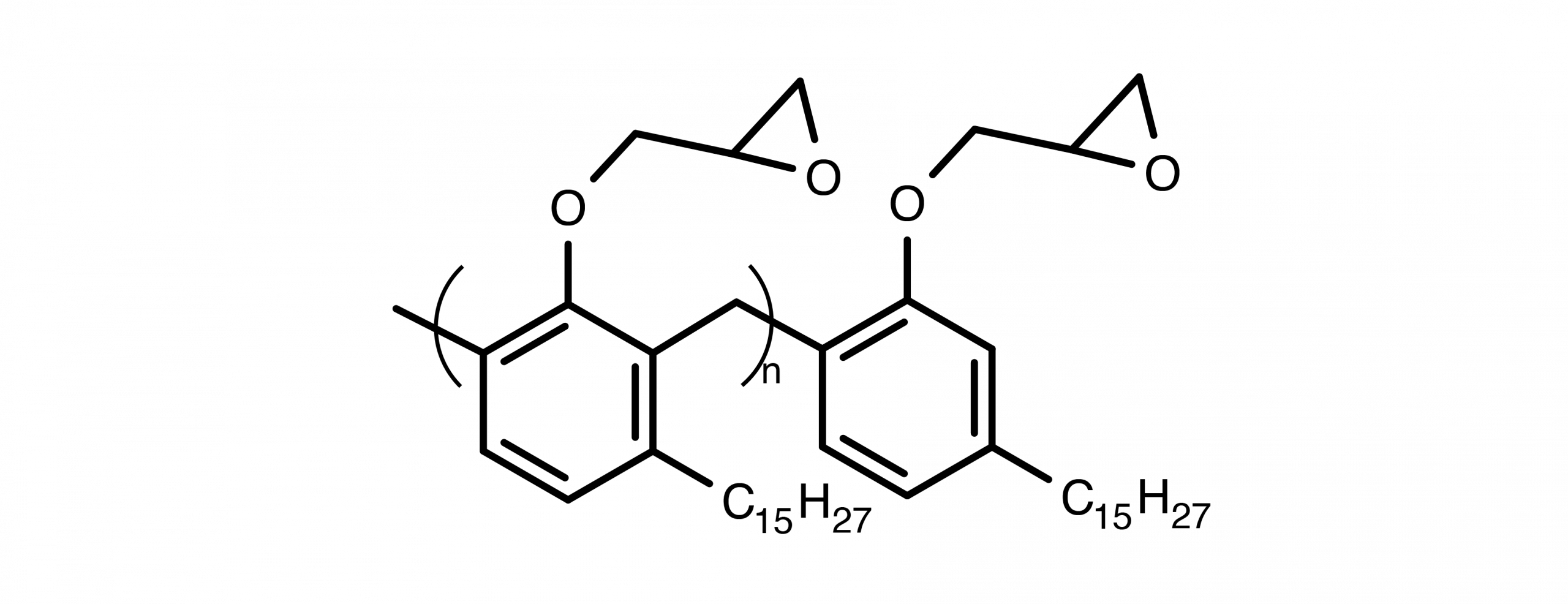

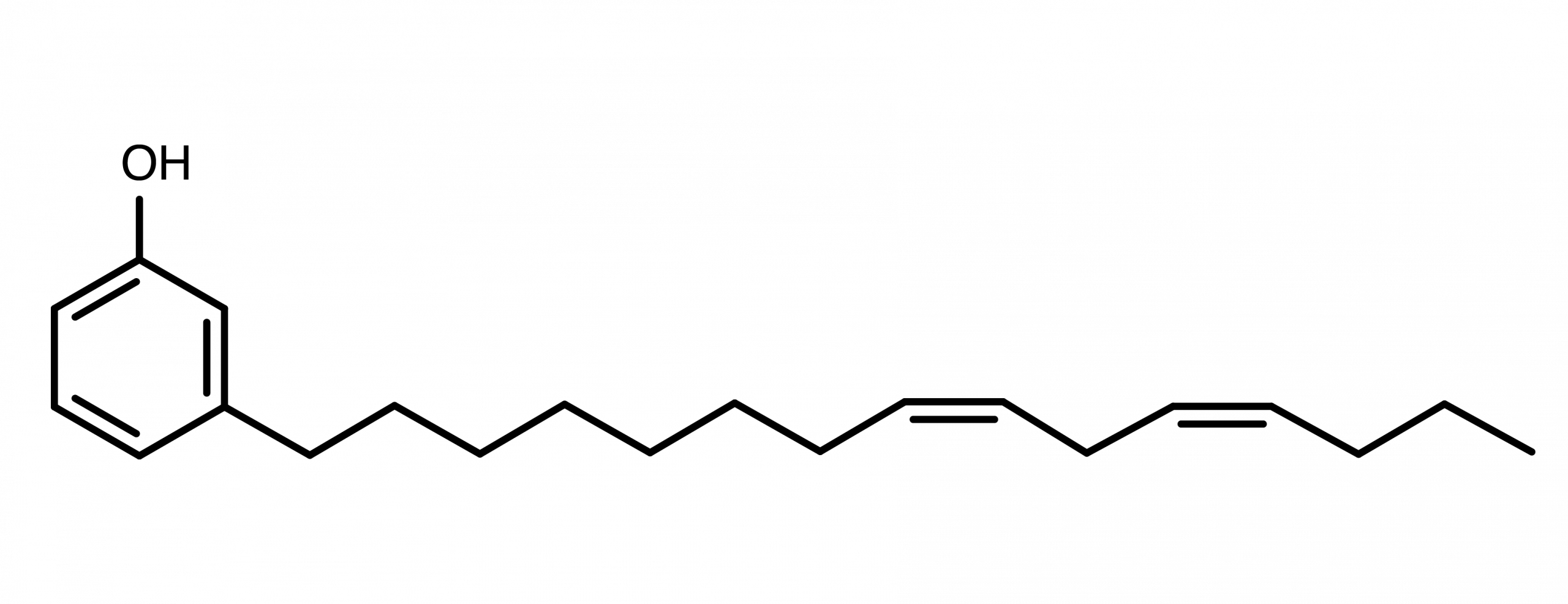

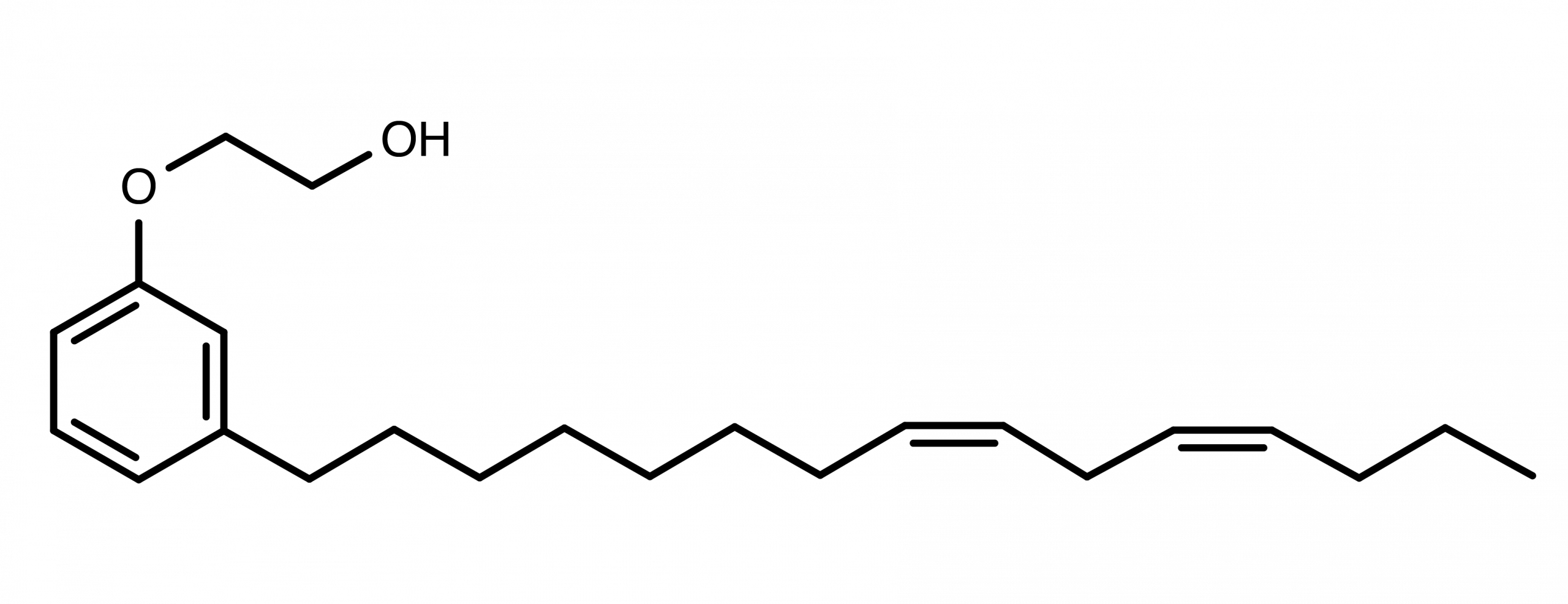

Monofunctional Epoxy Diluent Series

The Cardolite family of monofunctional epoxy diluents delivers efficient viscosity reduction and consistent performance. NC-513 is the standard grade, while Ultra LITE 513 offers higher purity, lower viscosity, and very light color, making it an excellent choice over traditional monofunctional glycidyl ether diluents.

Key Benefits:

- High dilution efficiency

- High flexibility

- High water and chemical resistance

- Good toughness and thermal shock resistance

- Good epoxy resin and curing agent compatibility

- Alternative to other monofunctional glycidyl ethers

- 100% bio-based material

NC-513

Cardolite NC-513 is a low viscosity, monofunctional epoxy reactive diluent designed for coatings, adhesives, and other epoxy applications.

– Adds flexibility and lowers viscosity while maintaining performance

– Excellent chemical and water resistance

– Increased thermal shock resistance

Ultra LITE 513

Cardolite Ultra LITE 513 is a very light color, low viscosity, monofunctional epoxy reactive diluent designed for coatings, adhesives, and other epoxy applications.

– Adds flexibility and lowers viscosity while maintaining performance

– Excellent chemical and water resistance

– Increased thermal shock resistance