Phenalkamide Benefits

Versatile performance

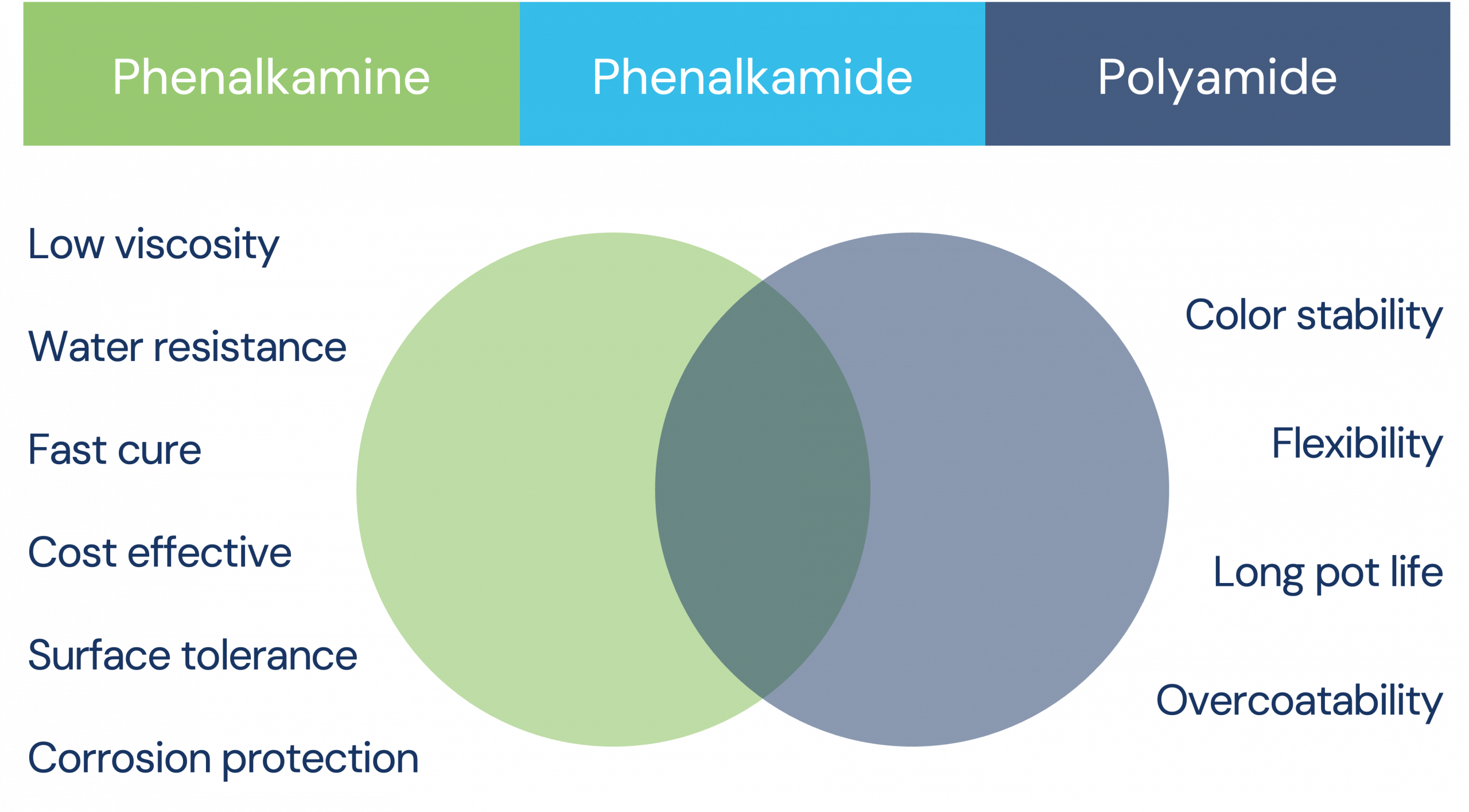

Phenalkamide curing agents deliver enhanced performance, reliability, and cost efficiency across applications traditionally served by polyamides. Their versatility allows manufacturers to simplify formulations, using a single product across diverse conditions and end uses.

Key advantages over traditional polyamides:

- Streamlines formulations, reducing the need for multiple curing agents

- Performs across a wide range of temperatures and substrates

- Ensures reliable results even at low temperatures or high humidity

- Cost-effective solution without compromising quality

UV stability

Cardolite’s phenalkamide technology delivers strong performance with improved color stability. This allows formulators to achieve long-lasting strength and protection without sacrificing appearance.

Learn more about our phenalkamide portfolio and how it can enhance your next formulation.

Contact Us

For more information, please contact your sales representative or submit an inquiry on our site.

Contact Us

For more information, please contact your sales representative or submit an inquiry on our site.