Cardolite offers epoxy curing agents of various chemistries to meet the requirements of a broad range of applications. Our offering includes phenalkamines and phenalkamides both derived from CNSL as well as polyamides and modified cycloaliphatic amines. Coatings formulators will find good options for industrial, marine and protective, transportation and flooring applications. Adhesives formulators will also encounter solutions for structural, building and construction, automotive and electronic systems. In addition, some of our low viscosity, solvent-free epoxy curing agents are excellent choices for composite applications looking to incorporate bio-content. Moreover, many of our curing agents are suitable for specialty applications such as electronics, and potable water and food contact.

PERFORMANCE BENEFITS

SOLVENT-FREE CURING AGENTS FOR MARINE & PROTECTIVE COATINGS

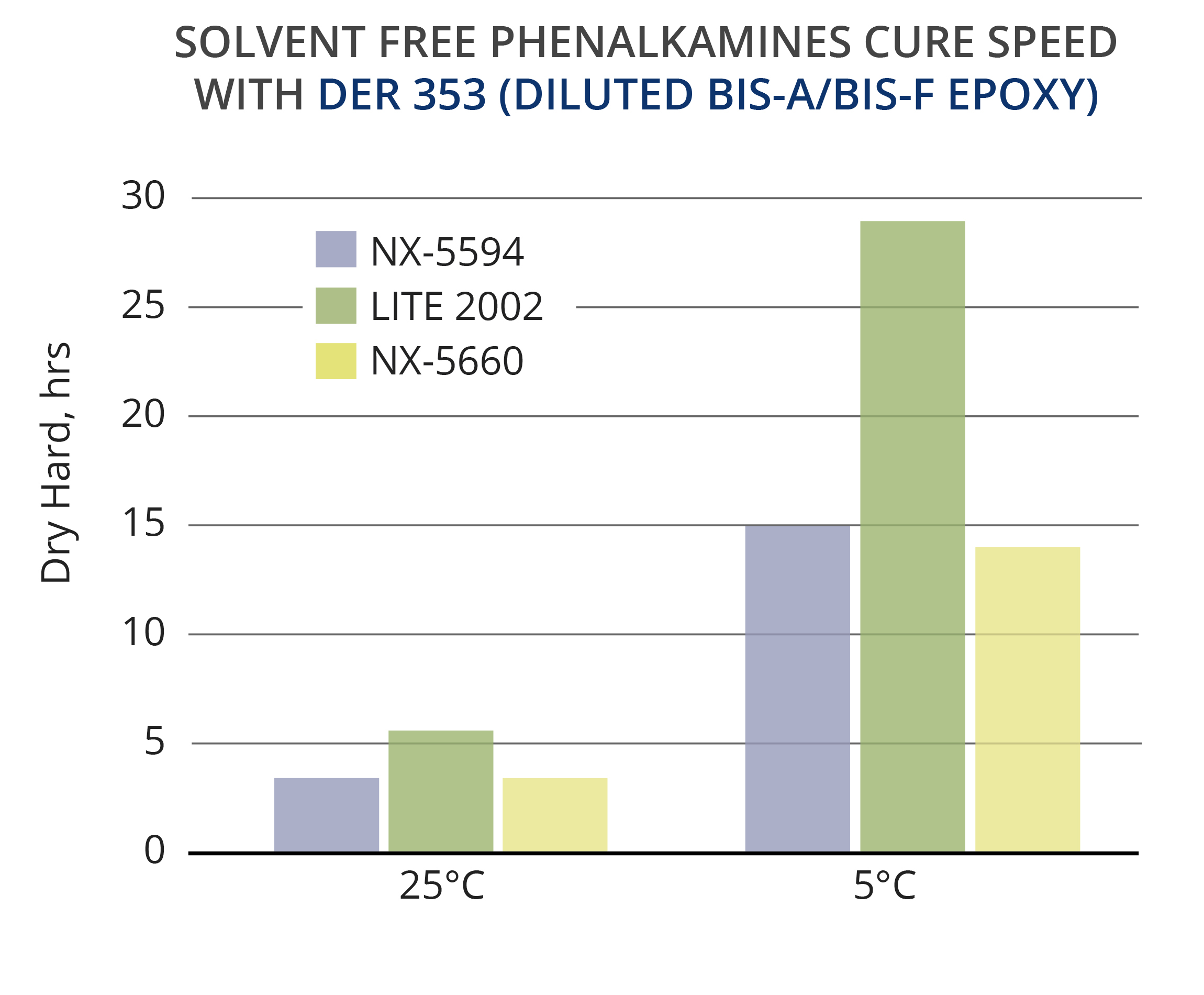

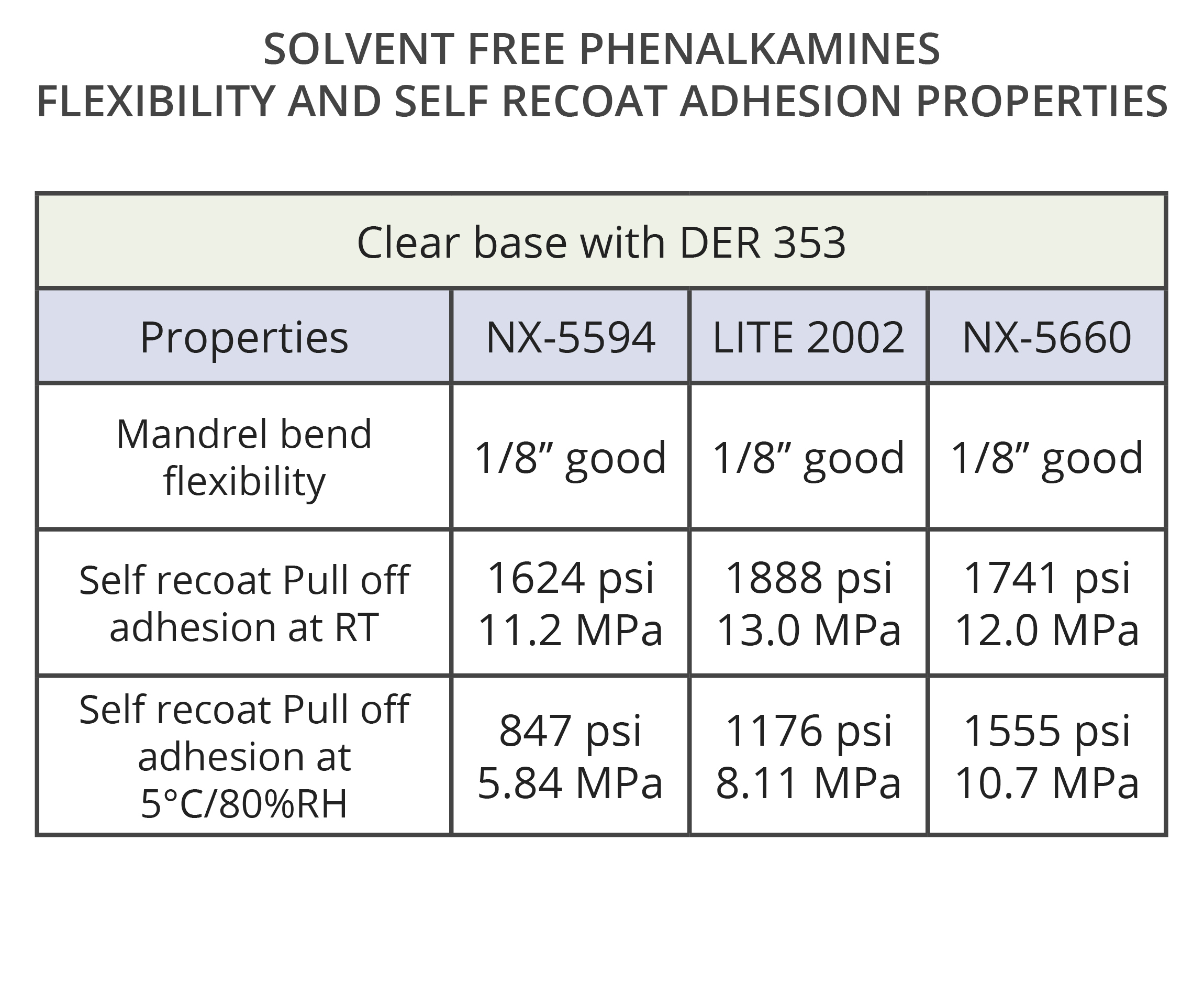

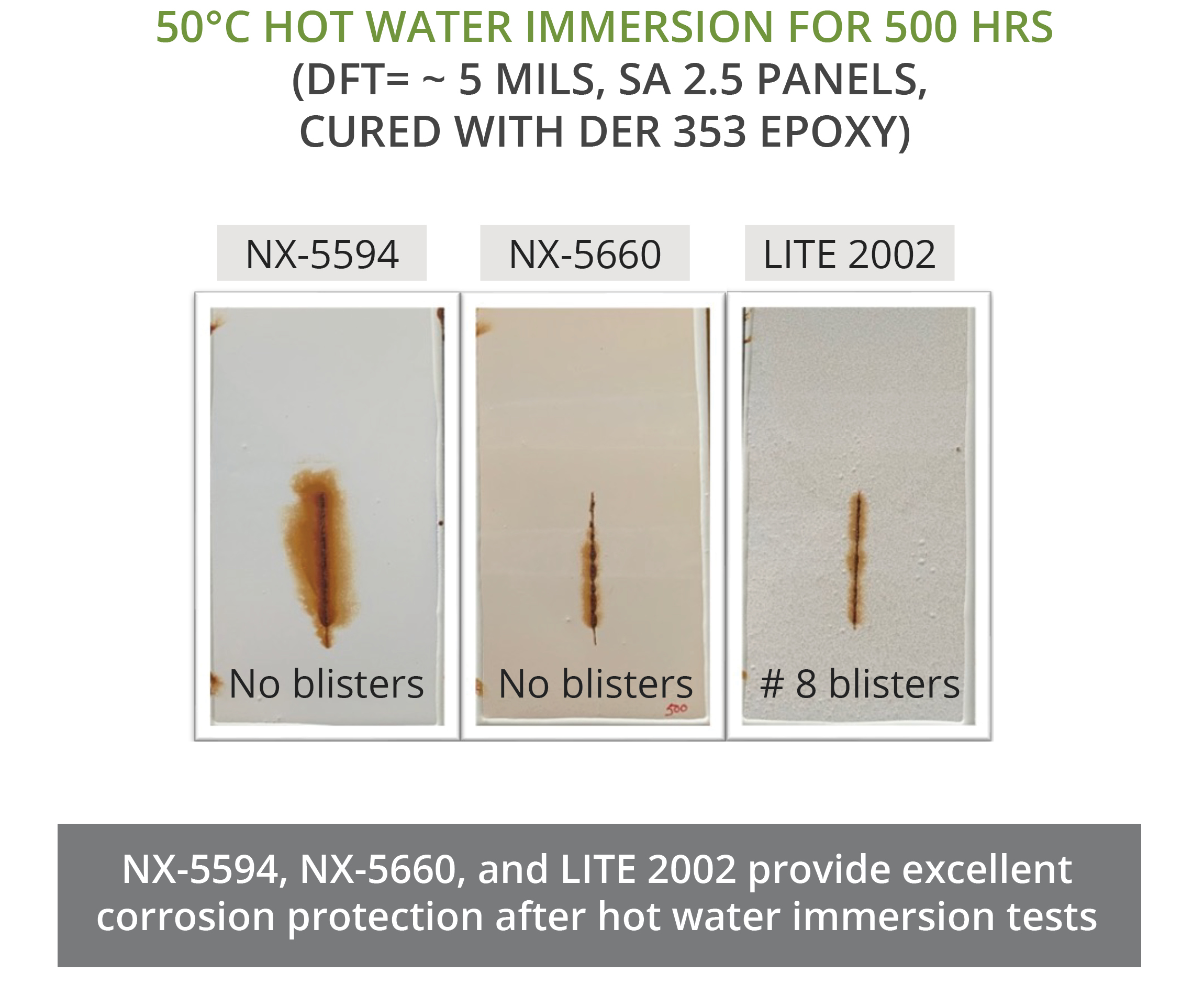

Cardolite offers many low viscosity curing agents for solvent free epoxy primers and coatings. Recently developed NX-5660, and NX-5594 and LITE 2002(LP) are excellent options to deliver high performance to low/zero VOC coatings. NX-5660 and NX-5594 offer very fast cure at low temperatures even in heavily diluted systems, while LITE 2002(LP) offers fast cure with longer pot life. All three curing agents provide long term corrosion protection on surfaces exposed to harsh conditions and show very good re-coatability and mechanical properties. NX-5660 and NX-5594 have shown excellent cathodic disbondment resistance and good performance after immersion in hot water.

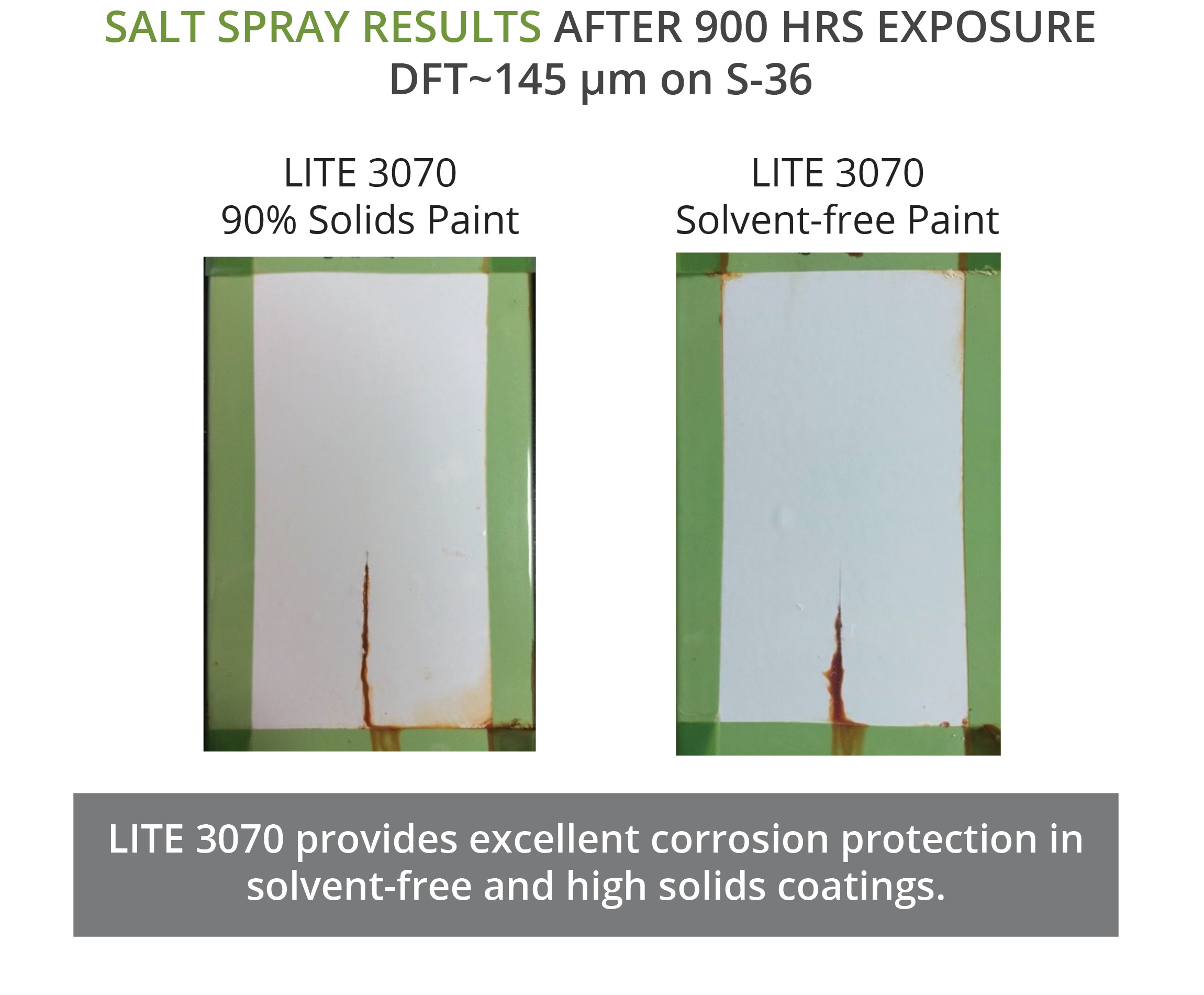

NEW LITE 3070 PHENALKAMIDE – FAST CURE WITH LONG POT LIFE

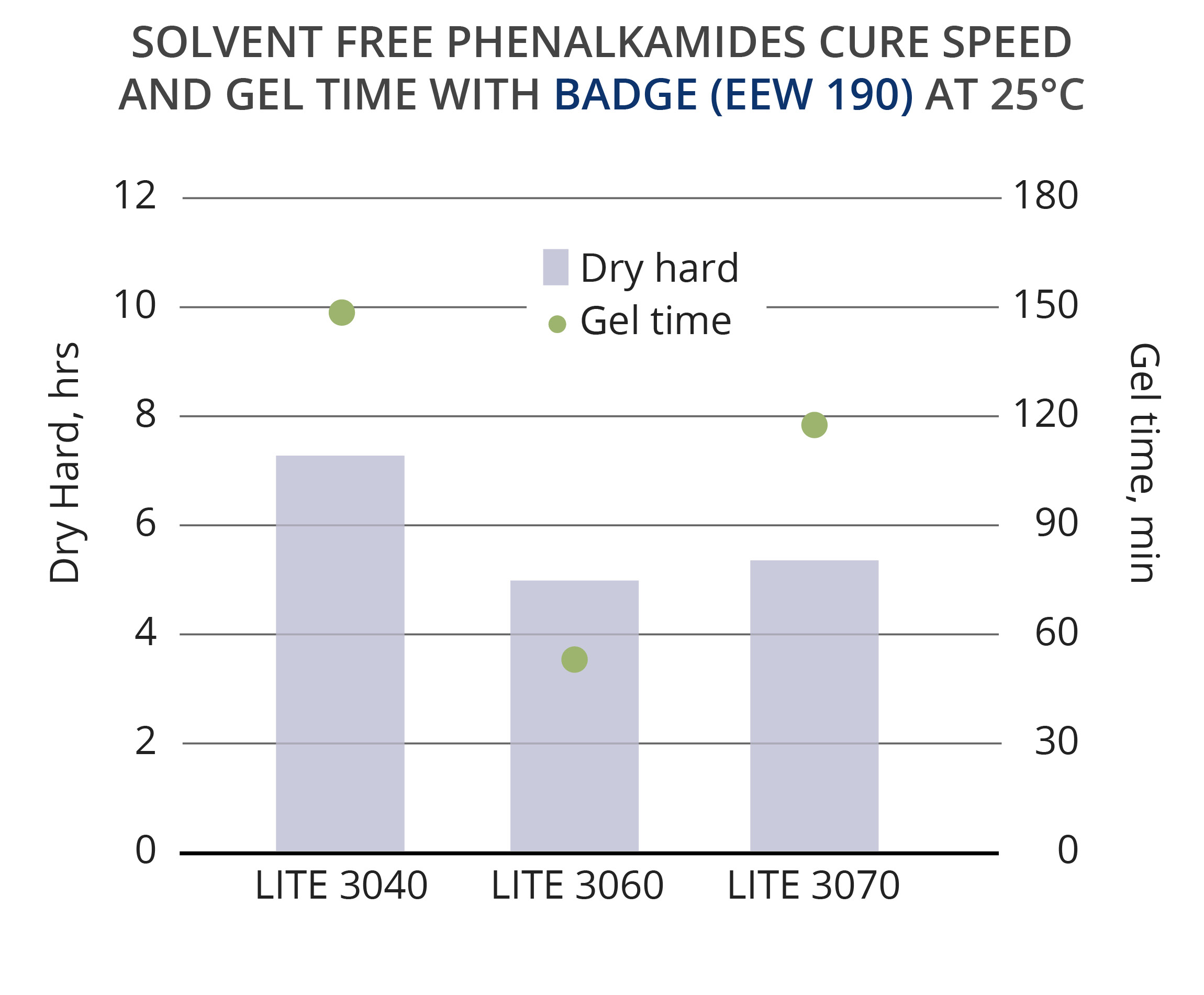

New phenalkamide, LITE 3070, provides fast dry times at room temperature while also delivering a long pot life and working time. This epoxy curing agent can be formulated in zero and low VOC epoxy systems due to its low viscosity. LITE 3070 is suitable for coatings, adhesives and any epoxy application that require good weatherability and protection coupled with good reactivity and friendly application and handling properties. When formulated in high solids and solvent free coatings, LITE 3070 demonstrated excellent anticorrosion performance as seen in salt spray tests. Moreover, this material provides very good intercoat adhesion even at low temperature and high humidity, and good adhesion to metal substrates and flexibility. As with other phenalkamides, LITE 3070 delivers low yellowing upon UV exposure.

Our phenalkamides offer benefits of phenalkamines and polyamides in one technology. While they inherited the fast cure speed even at lower temperatures and excellent corrosion protection of phenalkamines, they also deliver the good flexibility, UV resistance and long overcoatability seen with polyamides. To learn more visit our Phenalkamide Technology page.

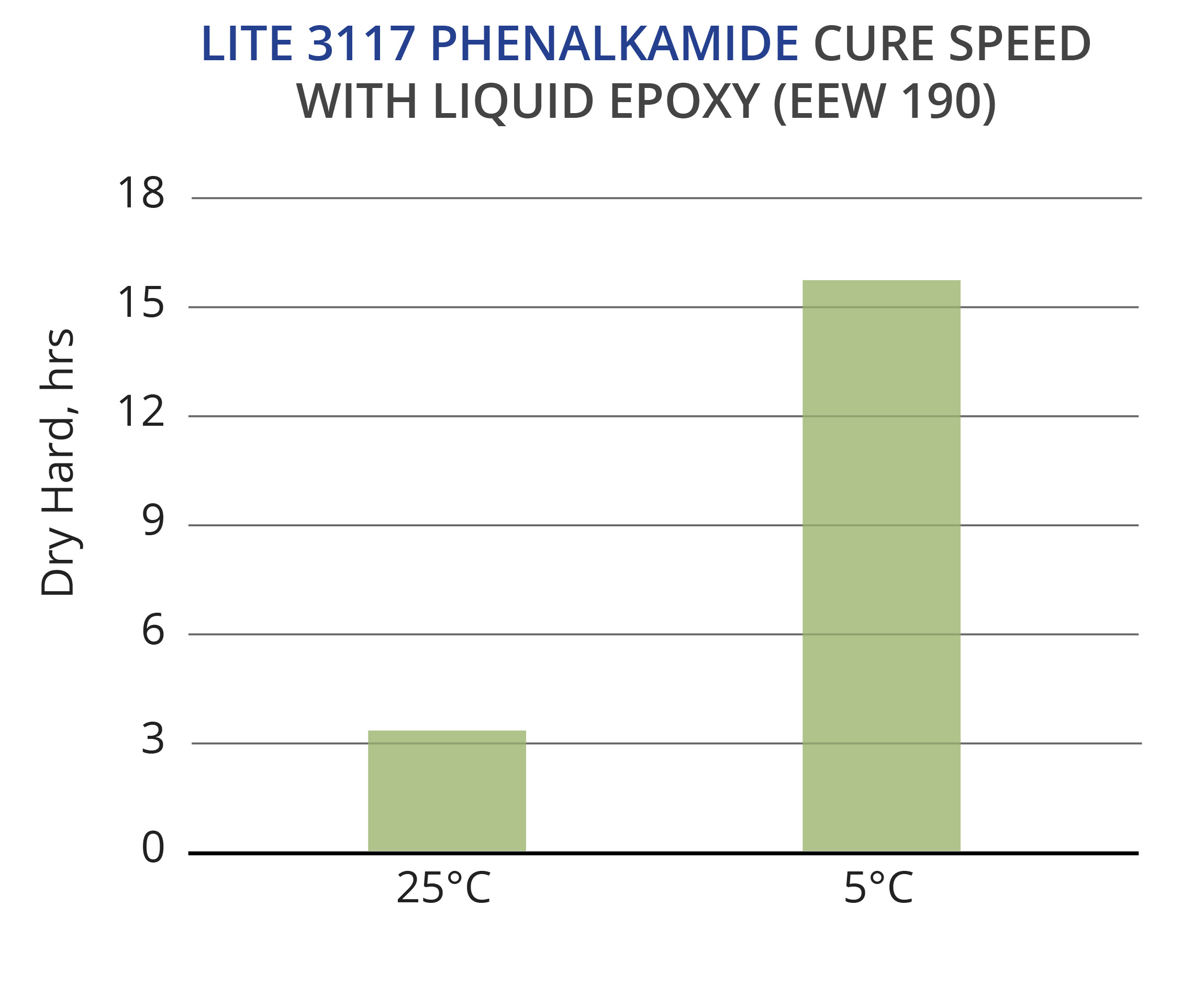

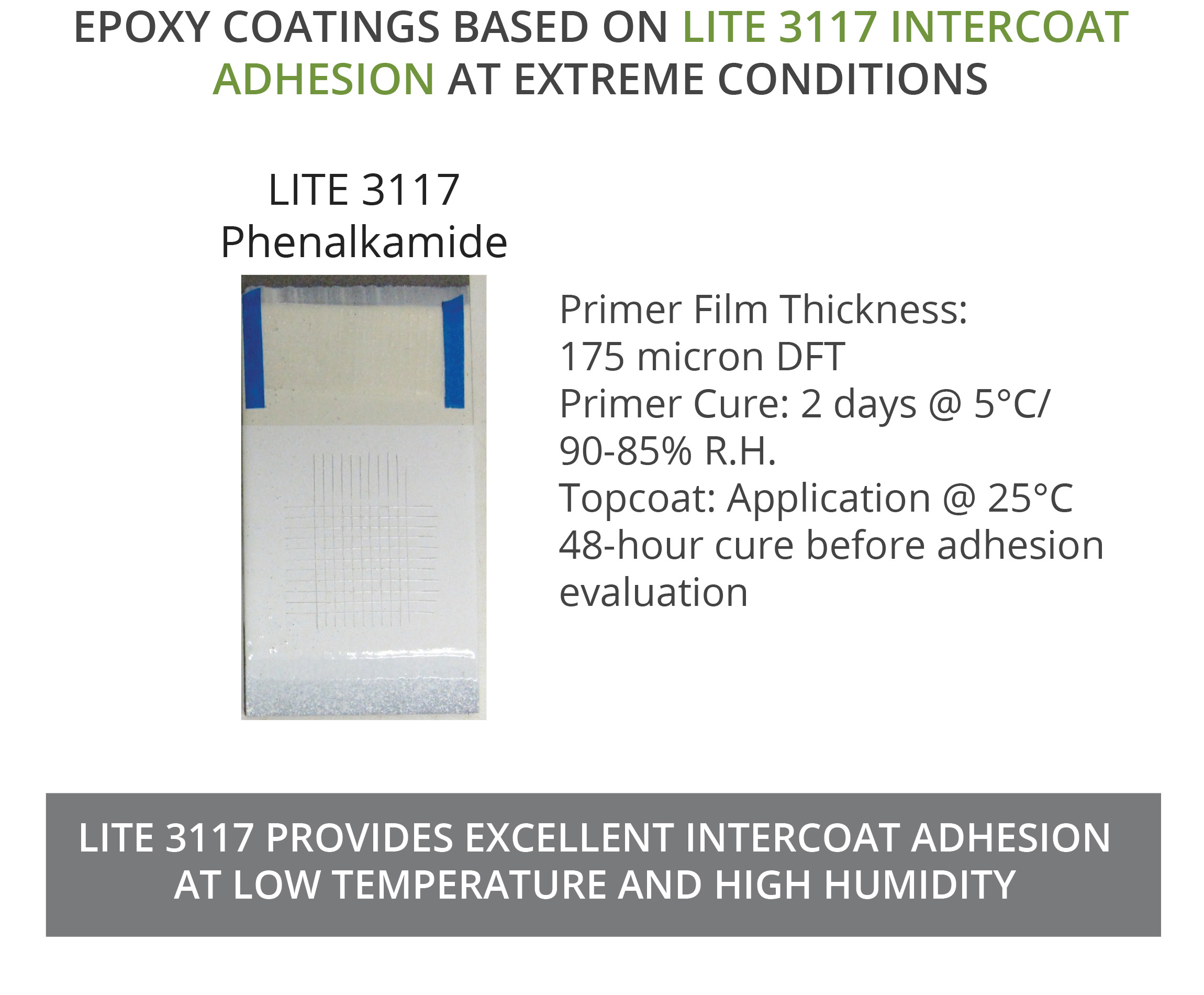

INTERCOAT ADHESION AT HARSH CONDITIONS

Many protective coatings systems are comprised of a primer and a topcoat. Commonly, the coating application takes place at a job site without control of environmental conditions such as temperature and humidity. Even though most coatings show good cure properties and intercoat adhesion at standard application conditions, they may fail if cured at lower temperatures specially in combination with higher humidity. Phenalkamide LITE 3117 provides excellent cure speed even at 5°C allowing formulators to continue the work in colder winter days. In addition, LITE 3117 retains excellent intercoat adhesion to topcoats when cured at 5°C/ 90-85% R.H. for only 2 days.

Our phenalkamide product line offers a good balance between fast cure and long pot life while delivering good UV resistance and long-term corrosion protection. To learn more visit our Phenalkamide Technology page.

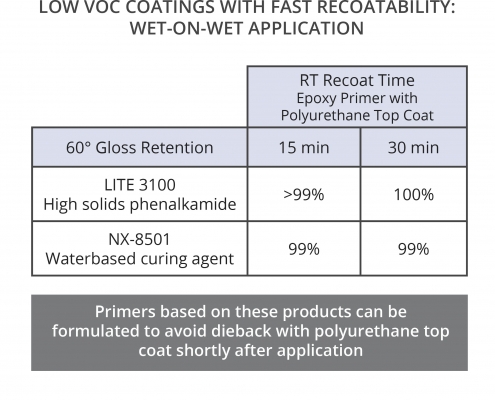

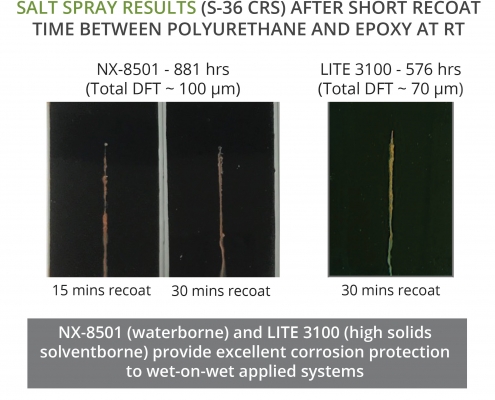

EXCELLENT WET-ON-WET RECOATABILITY

Typically, epoxy primers fully dry prior to being top coated with another coating layer. However, it is not unusual for applicators to add a second layer of coating before the primer has completely cured. For instance, polyurethanes are commonly applied over epoxy systems after short intervals in automotive refinish and transportation markets. This quick recoatability increases productivity and minimizes asset downtime. In this type of application referred to as wet-on-wet recoat, the shorter the recoat interval the better. Some projects require epoxy curing agents that can provide recoat times as short as 15-30 minutes to the epoxy coatings. If the epoxy + polyurethane system is not properly designed, film appearance can be compromised. As a result, an effect known as “die back” causes lower gloss of the polyurethane top coat.

Our evaluations have shown primers based on many of our phenalkamines and phenalkamides deliver very fast recoat times without hurting the film appearance. Also, they still provide excellent corrosion protection to the substrate as shown in the graphs below.

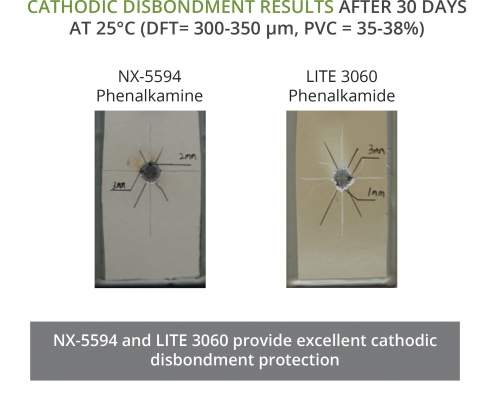

EXCELLENT CATHODIC DISBONDMENT PROTECTION

Cardolite CNSL-based epoxy curing agents provide excellent cathodic disbondment protection. Cathodic disbondment is an important test to evaluate the behavior of coatings that can be subjected to sacrificial cathodic protection as done in pipelines and other applications.

As examples, phenalkamide and phenalkamine grades LITE 3060 and NX-5594, respectively, underwent cathodic disbondment testing at 25°C for 30 days. No blisters or peeling were observed in the coating films and the maximum and minimum delamination from the holiday were low as indicated on the panels. The coatings kept good adhesion to the substrate without delamination, and the exposed metal area was free of rust. In addition, those grades are free of solvent and low in viscosity, therefore enabling very low VOC coatings. Both LITE 3060 and NX-5594 provide long-term corrosion protection as demonstrated in salt spray tests as well.

Other CNSL-based epoxy curing agents that provide excellent corrosion and cathodic disbondment protection are also available. Please check with your sales representative for further product recommendations.

CURING AGENT PRODUCT LINES

PHENALKAMINE EPOXY CURING AGENTS

Our phenalkamines are made through a Mannich reaction using cardanol as starting material. They provide very fast cure even below zero temperatures and excellent adhesion and corrosion protection even on immersed surfaces. Similarly, in adhesive applications, phenalkamines deliver very fast bond strength development to various substrates under strenuous conditions of cold temperatures and wet environments (even under water). Additionally, phenalkamines can be applied in a wide range of conditions and show good adhesion even to non-prepared surfaces, lowering application risk failures.

Moreover, through our Ultra LITE proprietary technology, very light color phenalkamines have been developed. The long chain of cardanol in the backbone of phenalkamine epoxy curing agents provides low viscosity and enables solvent free and very high solids coatings. In addition, use levels are non-critical and formulation friendly with 2:1 and 1:1 pack ratios possible.

Phenalkamines are an excellent option for coatings, adhesives, and composite applications.

PHENALKAMIDE EPOXY CURING AGENTS

Cardolite phenalkamides offer epoxy systems excellent corrosion protection and fast cure while maintaining long pot life, good flexibility and UV resistance, and extended overcoat window. In adhesives, phenalkamides can be used to develop high strength epoxy systems that require high mechanical properties and good thermal resistance. Both coatings and adhesives can benefit from phenalkamides ability to bond well to various substrates such as concrete, blasted and smooth metals, composites and some plastics.

The balance properties of phenalkamides allows for universal use in coating and adhesive applications during all four seasons of the year. DTM coatings are also possible with phenalkamides for higher efficiency. Some grades are drop-in alternatives to commercial polyamides to allow for easy substitution in formulations. High solids and solvent free grades are also available to enable low VOC and low viscosity epoxy systems that cannot be achieved with polyamide chemistry.

WATERBORNE TECHNOLOGY

The NX-8000 Series waterborne line of curing agents enables zero and low V.O.C. epoxy coatings with solvent-like performance. Cardolite offers a variety of grades that meet the needs of flooring, industrial, container, transportation and protective coatings applications. Building and construction adhesives can also benefit from this technology.

In our offering, formulators will find grades that can protect and bond to various surfaces including challenging substrates such as galvanized steel and aluminum. In addition to excellent corrosion protection, our grades provide wide curing conditions and excellent compatibility with various epoxy dispersion resins. As examples, compatibility with epoxy resin and fast cure even at 10°C and 80% RH can be achieved with NX-8101. Very long pot life and fast recoatability are made possible with NX-8401. Good UV resistance and quick wet-on-wet systems are delivered by NX-8501.

Cardolite also offers water soluble curing agents diluted in 1-methoxy-2-propanol and other solvents upon request, for use in waterborne zinc rich primers or other water-based applications.

EPOXY CURING AGENT SELECTION TABLE

| Curing Agent | Color (Gardner) | Solids (%) | Viscosity (cPs) @25C | AHEW | 25/5°C Dry Hard (hr) | Chemistry | Description | Recommended Applications* | Documents |

|---|---|---|---|---|---|---|---|---|---|

| LITE 3000 | 8 | 70 | 2400 | 256 | 5/17 | phenalkamide | 1st gen phenalkamide | M&P, Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| LITE 3005 | 11 | 70 | 1700 | 256 | 8/18 | phenalkamide | Cost effective and direct replacement of high MW and viscosity polyamides | M&P, Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| LITE 3025 | 8 | Solvent-free | 34000 | 103 | 7/n.a. | phenalkamide | Direct replacement of standard medium MW and viscosity polyamides with faster dry time and hardness development and better UV resistance | M&P, Ind&Trans, TP, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| LITE 3040 | 8 | Solvent-free | 5000 | 118 | 7.3/29 | phenalkamide | Low viscosity, excellent flexibility and overcoatability, and good dry color stability and corrosion protection | M&P, Ind&Trans, TP, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| LITE 3060 | 8 | Solvent-free | 850 | 104 | 5/17.5 | phenalkamide | SF, very low viscosity, good color stability, excellent cathodic disbondment protection and adhesion | M&P, Ind&Trans, CP, TP, B&C Adh, I&T Adh, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| LITE 3070 | 8 | Solvent-free | 850 | 107 | 5.5/22 | phenalkamide | Solvent-free, very low viscosity, fast cure with long pot life, excellent corrosion protection. | M&P, Ind&Trans, CP, TP, B&C Adh, I&T Adh, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| LITE 3100 | 8 | 80 | 4500 | 150 | 4/13 | phenalkamide | 1st gen with increased cure speed, higher solids, and lower use level | M&P, Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| LITE 3117 | 8 | 80 | 4500 | 150 | 3.5/16 | phenalkamide | Modified LITE 3100 with excellent intercoat adhesion at low temperatures and high humidity | M&P, Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| NX-5052 | 11 | Solvent-free | >100000 | 179 | 4.5/18 | phenalkamide | NX-5052 is the undiluted version of LITE 3005 | M&P, Ind&Trans, TP, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| GX-5135 | 8 | 80 | 2500 | 165 | 3/8 | phenalkamine | Faster version of NX-5110, high solids | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| GX-6027 | 7 | Solvent-free | 950 | 76 | 3/8.8 | phenalkamine | Light color version of NX-5594 | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| LITE 2001 | 10 | Solvent-free | 28000 | 132 | 3/12.5 | phenalkamine | Light color | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS(EU) |

| LITE 2001LV | 10 | Solvent-free | 2500 | 125 | 7/17 | phenalkamine | Low viscosity, light color | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| LITE 2001X90 | 10 | 90 | 3800 | 144 | 9/17 | phenalkamine | Light color, solvent cut for good handling | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| LITE 2002 | 10 | Solvent-free | 450 | 104 | 6/20 | phenalkamine | Low viscosity, light color, excellent anticorrosion | M&P, Ind&Trans, I&T Adh, B&C Adh, 2K comp | TDS MSDS (USA) MSDS (EU) |

| LITE 2002LP | 10 | Solvent-free | 700 | 104 | 7/21 | phenalkamine | LITE 2002 with Improved pot life | M&P, Ind&Trans, B&C Adh, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| LITE 2010LV | 10 | Solvent-free | 4100 | 125 | 3/13.5 | phenalkamine | Low viscosity, light color, excellent film at extreme conditions | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| LITE 2401 | 5 | Solvent-free | 90 | 61 | n/a | phenalkamine | Low viscosity, light color, better mechanical properties, chemical resistance | I&T Adh, 2K comp | TDS MSDS (USA) MSDS (EU) |

| LITE 2402 | 11 | Solvent-free | 105 | 56 | n/a | phenalkamine | Comparable to LITE 2401 with higher Tg | I&T Adh, 2K comp | TDS MSDS (USA) MSDS (EU) |

| LITE 2562 | 9 | 65 | 1500 | 174 | 2.5/7.5 | phenalkamine | Light color, fast cure, good blush resistance and adhesion | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| LITE 5262 | 9 | ≤ 5% solvent | 2500 | 114 | 2.75/11 | phenalkamine | Low VOC, very fast cure, excellent corrosion protection and adhesion to various substrates | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NC-540 | 15 | Solvent-free | 2000 | 81 | 3.5/13 | phenalkamine | Low viscosity, surface tolerant, solvent free | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NC-541 | 16 | Solvent-free | 28000 | 130 | 5/15.5 | phenalkamine | Low temperature cure, surface tolerant, excellent anticorrosion | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NC-541LV | 15 | Solvent-free | 2300 | 125 | 7/24+ | phenalkamine | Low viscosity for high solids | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NC-541X90 | 16 | 90 | 4000 | 144 | 5/13 | phenalkamine | Solvent cut for good handling | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NC-556X80 | 14 | 80 | 4500 | 135 | 3.5/12 | phenalkamine | Fast cure and hardness development, high solids | Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NC-557 | 14 | Solvent-free | 1100 | 95 | 7/16.5 | phenalkamine | Fast cure, excellent adhesion, solvent free | Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NC-558 | 17 | Solvent-free | 900 | 95 | 10/27 | phenalkamine | Low viscosity, excellent adhesion to unprepared substrates, solvent free | M&P, Ind&Trans, CP, I&T Adh, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NC-562 | 14 | 65 | 1300 | 174 | 3/9 | phenalkamine | Fast cure, good blush resistance and adhesion | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NC-565 | 14 | 65 | 1300 | 174 | 3/9 | phenalkamine | Fast cure, good blush resistance and adhesion | M&P, Ind&Trans | TDS MSDS (USA) MSDS (CA) |

| NC-641 | 16 | Solvent-free | 25000 | 130 | 4/13.5 | phenalkamine | Lower free amine version of NC-541, with better film appearance and slightly faster cure | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-2003 | 10 | Solvent-free | 620 | 95 | 4.5/18.5 | phenalkamine | Fast cure, excellent adhesion, light color, solvent free | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-2003D | 13 | Solvent-free | 700 | 95 | 4.5/15 | phenalkamine | Fast cure, excellent adhesion, solvent free | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-2007 | 4 | Benzyl alcohol | 265 | 113 | 2/16 | phenalkamine | Fast cure and hardness, good flow and yellowing resistance | Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| NX-2009 | 7 | Benzyl alcohol | 370 | 95 | 4/12 | phenalkamine | Good film appearance, yellowing resistance, fast cure, cost effective | Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| NX-2016 | 15 | 75 | 12000 | 151 | 2/6.5 | phenalkamine | Fast cure, higher viscosity | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-2018 | 16 | 75 | 8400 | 151 | 3/9 | phenalkamine | Fast cure, cost effective | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-2047 | 18+ | Solvent-free | 25000 | 190 | 6.2/25 | phenalkamine | Very cost effective phenalkamine | M&P, Ind&Trans, CP | TDS MSDS (USA) MSDS (EU) |

| NX-4943 | 14 | Solvent-free | 1800 | 82 | 4/14 | phenalkamine | Excellent chemical resistance, solvent free | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5050 | 18 | 80 | 770 | 190 | 2/7.5 | phenalkamine | Very fast cure, high solids, low viscosity | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-5110 | 8 | 80 | 2500 | 165 | 3.19.6 | phenalkamine | Light color version of NX-5556M | M&P, Ind&Trans | TDS MSDS (USA) |

| NX-5198 | 11 | 95 | 140 | 179 | 2.4/13 | phenalkamine | Fast cure, very low viscosity, cost effective | Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5444 | 8 | 80 | 4300 | 190 | 1.5/6 | phenalkamine | Fast hardness development, good flexibility, high solids | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-5445 | 18 | 78 | 1800 | 256 | 2/6.5 | phenalkamine | Very fast cure, high solids, low viscosity | M&P, Ind&Trans | TDS MSDS (USA) SDS (EU) |

| NX-5454 | 11 | Solvent-free | 1080 | 133 | 2/7.5 | phenalkamine | Very fast cure, excellent film appearance, solvent free | M&P, Ind&Trans, CP, I&T Adh, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5459 | 15 | 70 | 1650 | 164 | 4/12 | phenalkamine | Fast cure, high solids | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-5556M | 15 | 80 | 2500 | 165 | 2/11 | phenalkamine | Excellent corrosion protection, similar properties to NC-562, high solids | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NX-5567 | 15 | Solvent-free | 770 | 66 | 3/10 | phenalkamine | Excellent chemical resistance, fast cure | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5594 | 14 | Solvent-free | 950 | 76 | 2.5/8 | phenalkamine | Very fast cure, excellent cathodic disbondment and chemical resistance properties | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5607 | 10 | Solvent-free | 2490 | 95 | 2/9 | phenalkamine | Fast bond strength development, high mechanical strength and good durability. | B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5608 | 10 | Solvent-free | 3350 | 95 | 2.5/12 | phenalkamine | Fastest bond strength development, high Tg and mechanical strength. | B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-5619 | 8 | Solvent-free | 425 | 104 | n/a | phenalkamine | Room temperature cure, high bio-content, chemical resistance | 2K Comp | TDS MSDS (USA) MSDS (EU) |

| NX-5620 | 13 | Solvent-free | 830 | 82 | n/a | phenalkamine | Room temperature cure, high bio-content, chemical resistance | 2K Comp | TDS MSDS (USA) MSDS (EU) |

| NX-5653 | 10 | Solvent-free | 1100 | 132 | 2/6.7 | phenalkamine | Very fast hardness development at low temp. No free phenol. Excellent film appearance. | M&P, Ind&Trans, CP | TDS MSDS (USA) MSDS (EU) |

| NX-5660 | 14 | Solvent-free | 600 | 110 | 2.5/10 | phenalkamine | Very fast cure, excellent cathodic disbondment and corrosion resistance properties | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-6019 | 11 | Solvent-free | 1100 | 133 | 2.5/10 | phenalkamine | Better labeling version of NX-5454 | M&P, Ind&Trans, CP, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NX-6654 | 10 | Solvent-free | 1200 | 132 | 2.3/8.8 | phenalkamine | Very fast hardness development at low temp. No free phenol. Excellent film appearance. | M&P, Ind&Trans, CP | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2009 | 1 | Benzyl alcohol | 330 | 95 | 6/22 | phenalkamine | Excellent film appearance, yellowing resistance, cost effective | Ind&Trans, TP, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2009SF | 1 | Solvent-free | 5900 | 62 | 7/22 | phenalkamine | Undiluted Ultra LITE 2009 | Ind&Trans, TP, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2009H | 1 | Benzyl alcohol | 150 | 95 | 5/19 | phenalkamine | Faster hardness development, good yellowing resistance and film appearance | Ind&Trans, TP | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2009HSF | 2 | Solvent-free | 550 | 62 | n.a. | phenalkamine | Undiluted Ultra LITE 2009H | Ind&Trans, TP, I&T Adh, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| NT-1515 | 8 | Solvent-free | >100000 | 198 | n.a. | polyamide | Standard high molecular weight and viscosity polyamide | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) |

| NT-1515X70 | 8 | 70 | 500 at 40°C | 283 | 10/n.a. | polyamide | NT-1515 in xylene | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NT-1515I73 | 8 | 73 | 1800 | 271.5 | n.a. | polyamide | NT-1515 in isopropanol | M&P, Ind&Trans | TDS MSDS (USA) |

| NT-1541 | 9 | Solvent-free | >100000 | 198 | n.a. | polyamide | Cost effective replacement for standard high molecular weight and viscosity polyamides | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NT-1541I73 | 8 | 73 | 1800 | 271.5 | 10/n.a. | polyamide | NT-1541 in isopropanol | M&P, Ind&Trans | TDS MSDS (USA) |

| NT-1541X70 | 8 | 70 | 1600 | 283 | 10/n.a. | polyamide | NT-1541 in xylene | M&P, Ind&Trans | TDS MSDS (USA) MSDS (EU) |

| NT-1542 | 7 | Solvent-free | 40000 | 103 | 8/n.a. | polyamide | Standard medium molecular weight and viscosity polyamide | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NT-1544 | 8 | Solvent-free | 10000 | 97 | 9/n.a. | polyamide | Standard medium-low molecular weight and viscosity polyamide | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) MSDS (EU) |

| NT-1545 | 8 | Solvent-free | 3000 | 103 | 11/n.a. | polyamide | Low molecular weight and viscosity polyamide | M&P, Ind&Trans, B&C Adh, I&T Adh | TDS MSDS (USA) |

| NT-1550 | 8 | Benzy alcohol | 3500 | 133 | 6/n.a. | polyamide | Specially modified polyamide | M&P, Ind&Trans | TDS MSDS (USA) |

| NT-5901 | 1 | Benzy alcohol | 454 | 113 | 7.5/n.a. | modified cycloaliphatic amine | Good color stability, low viscosity, low color. | Ind&Trans, TP, 2K Comp | TDS MSDS (USA) MSDS (EU) |

| NX-8101 | 8 | 50% in water | 35000 | 270 | 3/9 | waterborne | Fast hardness development, excellent corrosion protection and stain resistance. Versions in glycols available. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8401 | white emulsion | 55% in water | 7000 | 290 | n.a. | waterborne | Easy handling, fast recoatability, excellent corrosion protection. | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8402 | white emulsion | 45% in water | 18000 | 316 | n.a. | waterborne | Easy handling, fast cure speed, excellent corrosion protection. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8501 | 8 | 80% in water | 5600 | 165 | n.a. | waterborne | Excellent corrosion protection and good yellowing resistance. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8502 | 6 | 45% in water | 15000 | 424 | n.a. | waterborne | Excellent corrosion protection with fast cure and long pot life | M&P, Ind&Trans, CP, B&C Adh | TDS |

*Abbreviations in the Applications column:

Marine and Protective Coatings – M&P

Industrial and Transportation Coatings – Ind&Trans

Solvent-free Floor Primers – CP

Top Coats – TP

Building and Construction Adhesives -B&C Adh

Industrial and Transportation Adhesives – I&T Adh

Two-component Composites – 2k Comp