RENEWABLE ALTERNATIVE WITH EXCELLENT PERFORMANCE

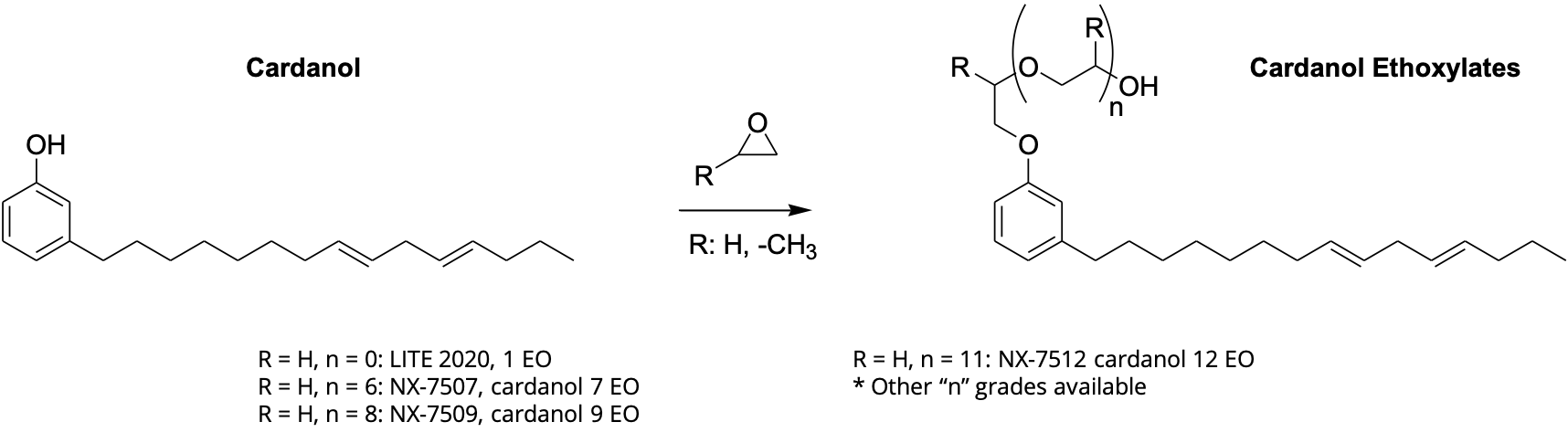

Cardolite surfactants are based on bio-based CNSL technology. They use distilled CNSL namely, Cardanol, as starting material which provides many benefits due to its unique chemical structure. The combination of its long aliphatic side chain with the alkoxylation of the phenolic hydroxyl results in balanced surfactant properties that can be fine tuned based on the number of ethylene oxide moles used.

Ethoxylated cardanol surfactants are good alternatives to nonyl phenol ethoxylates (NPEs) or alkyl phenol ethoxylates (APEs), and fatty alcohol ethoxylates, which are widely used in industrial products and home care and consumer goods. NPEs have raised concerns over the years and are believed to be harmful to our health and the environment. As a result, they continue to be phased-out of some formulations. In general, ethoxylated cardanols are low foaming, provide good emulsion stability, and show lower viscosity than ethoxylated nonyl phenol grades with the same number of EO moles. Hydrophilic–lipophilic balance (HLB) values can also be used for comparison and are provided in the properties table below.

Sold under the NX-7500 Series, these materials are suitable for applications such as metal working fluids, architectural paint, polyurethane foams, and leather and textiles. In polyurethane foams, cardanol surfactants may also partially replace silicones or natural oil type surfactants to deliver good flowability, reaction profiles and mechanical properties.

Metalworking Fluids

– Low foaming

– Excellent emulsion formation

– Bio-based from non-food chain source

Polyurethane Foams

– Good flowability and reactivity

– Good mechanical properties

– Bio-based from non-food chain source

Textiles & Leather

– Better labeling

– Good wetting (suitable for PUDs)

– Bio-based from non-food chain source

Architectural Paint

– Low foaming

– Better emulsion stability

– Bio-based from non-food chain source

CNSL-based Surfactant Properties

| Property (typical values) | LITE 2020 (1EO) | NX-7507 (7EO) | NX-7509 (9EO) | NX-7512 (12EO) |

|---|---|---|---|---|

| Color (Gardner) | 12 | 10 | 10 | 10 |

| Viscosity @ 25 °C (cps) | 90 | 180 | 200 | 360 |

| HLB values (calc.) | 2.6 | 10.1 | 11.4 | 12.8 |

| OH value (mg KOH/g) | 152 | 100 | 89 | 81 |

| Cloud point (2% in BDG 10%) | n.a. | 66 | 74.5 | 80 |

| Pour point (°C) | n.a. | 9 | 3 | 18 |

| Surface tension (mN/m) | n.a. | 53.0 | 50.1 | 43.7 |

| Foaming efficiency (ml at 0,1 wt% actives, 25 °C, initial/5 minutes) | n.a. | 24 / 23 | 28 / 27 | 47 / 42 |